MCC

Type Tested Low Voltage MCC

Low voltage switchboards are designed to fulfil various applications needs. It’s unique structure and flexible power modules are type-tested and certified by internationally accepted independent laboratories.

Cubicles up to 6800 A

Design

Design

Fits perfectly in commercial environments

Colours RAL 7035

Rigid and sturdy

Supporting structure 2 mm thick

Bent to increase rigidity

Die-cast metal corner part

Easy and quick to assemble

Assembly by a single person

Pre-assembled captive screws

120º screws for cover plates

Frame to remove all cover plates at once!

Up to 6800 A Main busbar

Click-in supports for functional units and busbar holders. No tools needed

600 Vac

Front and Rear Intervention

Internal and External applications.

ANSI-61 (RAL 7035) Gray

Energy Analyzer

Energy Monitoring Infrastructure

Surge arrester can be installed

Earth Leakage protection

Busbar connection is possible

Up to 120 / 200kA

Copper Busbar (Option Silver Plated)

Earth Bus

Neutral Busbar

MOTOR STARTERS / MS

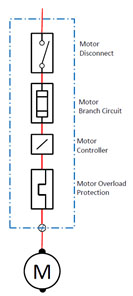

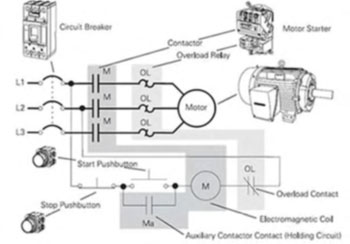

| Espan Motor starters series were designed to meet the equirements and flexibility frequently demanded in industrial applications. Featuring components that meet IEC design standards and UL horsepower ratings, Espan enclosed starters are UL508A approved and CSA certified. This means your panels will fulfill the rigorous requirements of UL508A and will have the quality and performance |

| Standard or CustomBy having most of the processes in Espan facilities we can manufacture not only the enclosed starters listed on this catalog, but also any other custom panel your application may require. Our Engineers will work together with you to provide the perfect solution for your application Espan offers options for both: Full Voltage Non‐Reversing Non‐Combination Starters and Full Voltage Non‐Reversing Combination Starters up to 250Hp at 600 Vac. Espan ’s Standard panel shops can manufacture any configuration of Non‐ Combination or Combination Starters for any low voltage horsepower ratings. Some examples are listed below: • Enclosed Contactors; • Full Voltage Reversing Starters; • Reduced Voltage Magnetic Starters (Part‐ Winding,Wye‐Delta);• Reduced Voltage Solid‐State Starters (Softstarters, VFD); • Multi‐Speed Starters; • Explosion Proof Starters; • Pump Panel Controllers  General engineering and plants General engineering and plants• Industries • Conveyor systems • Chemical industries including process engineering • Pharmaceutical industries • Automation of buildings, e. g. in air‐conditionings • Environmental plants • Power stations • Fresh water and sewage plants • Machine tools  | New Concepts Smaller size components allow selection of smaller enclosures which translates to cost savings. A wide range of ratings andframes allow the components to be more closely matched to your application. Our overload relays provide phase loss sensitivity, ambient temperature compensated for ‐4F to +140F (eliminating the need for additional heaters) and automatic reset for remote applications. A wide range of industrial applications are covered: Pumps, Industrial Washing machines, Compressors, Blowers, Cutting Machines, Conveyors, Lumber Processing and many others  Wherever motors are used, they must be controlled. In Basics of Control Components you learned how various control products are used to control the operation of motors. The most basic type of AC motor control, for example, involves turning the motor on and off. This is often accomplished by using a motor starter, which is made up of a contactor and an overload relay. The contactor's contacts are closed to start the motor a nd opened to stop the motor. This is complished electromechanically using start and stop pushbuttons or other pilot devices wired to control the contactor. The overload relay protects the motor by disconnecting power to the motor when an overload condition exists. An overload could occur, for instance, when a conveyor is jammed. Although the overload relay provides protection from overloads, it does not provide shortcircuit protection for the wiring providing power to the motor. For this reason, a circuit breaker or fuses are also used. Typically one motor starter controls one motor. When only a few geographically dispersed AC motors are used, the circuitprotection and control components may be located in a panel near the motor. |

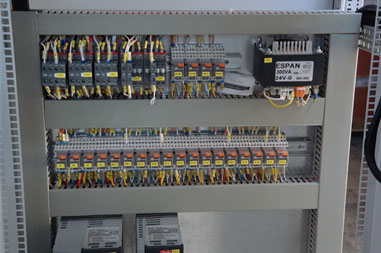

Motor Control Center MCC

| Features Motor control experience High‐quality components and workmanship Guaranteed, reliable and long service life High‐level short‐circuit withstand ratings Enhanced safety in operation and maintenance Latest technology motor starter and feeder units Optimum use of mounting space without sacrificing work space Multiple savings in installation, operation and maintenance. IMCC Motor Control Center * Type‐tested to IEC/EN 60439‐1 * Main bus rating up to 6000A Cu * Short‐circuit bracing: main bus ‐ @ 1 sec. 35/50/70/120 kA * Unit mounting: front fixed, removable or withdrawable, form 1 to 4b * Environmental: IP30, IP32, IP40, IP42, IP54, IP65 * Finish: RAL 7032, pebble‐gray to DIN 43 656  High quality components from All brand are the necessary ingredients for high quality control panels  | UMCC Motor Control Center * UL/CSA * Main bus rating up to 4000A Cu * Short‐circuit bracing: 50kA rms sym. standard, 65kA and 100kA rms sym. optional * Unit mounting: front or back‐to‐back, fixed or withdrawable * Environmental: NEMA Type 1 standard, * NEMA Type 12, 5, 2, 3R * Finish: exterior ‐ ANSI 61 light gray interior ‐ zinc‐plated or painted  High quality, advanced technology assemblies, designed, constructed and tested for Europa or international destinations, including CE applications Experienced is service * Building Automation and SCADA Systems * Water and Waste Water Treatment plants * Power Distribution and Energy Automation * Feed factories * Flour Factories * Cement Factories * Hydroelectric power plants (HES) * Industrial Oven Systems * For Machine Automation Plant Automation * Systems for Asphalt plants, All Brand Electric equipment is a worldrenowned, full‐line manufacturer of high quality industrial electrical and electroniccomponents, engineered assemblies and enclosures. Control panels with All Brand Electric equipment installed components are lab‐tested, application selected and fully coordinated for protection against short‐circuit, overload and motor inglephasing induced damages, etc. All Brand Electric equipment control panels can be engineered to protect, switch and control the connected equipment throughout their expected life. |