AUTOMATION

HEPP [ HES ]

HYDROELECTRIC POWER PLANTS

| As in other industries, energy and water industry also follows the latest trends and uses the latest technologies in the field of automation and control. What changes are primarily control systems for small hydro power plants. by combining the smart sensors and advanced algorithms it is possible to achieve much higher reliability and efficiency in energy production. "In this area there is still a great potential for application of technology nowadays quite common in other industries automation, enabling remote supervision and management of these power plants, as well as real-time monitoring of the status, performance |

- MAIN-PLC Synchronization, units, regulators, headpond remote I/O boards, power project and power panel manufacturing.

- Preparation of PLC and SCADA software and cable lists according to a preferred type of customer turbines

- Ensuring the management of the HV and LV power distribution and control system automation section

- Archiving of HV and LV alarm

- Control and monitoring of the unit start-stop sequence

- Emergency shut down sequence control, monitoring and archiving of the units

- Monitoring the unit phase diagrams

- Control, monitoring and archivinghe the unit HV breaker

- Control, monitoring and alarms of the inlet structure

- Archiving of alarm monitoring the oil level and temperature data

- Monitoring and archiving alarm conditions of Exciter and the communication with Governor structures

- Implementation of Load Shedding-taking scenario

- Flexible interface screens and pop-up structure accordance with the operator needs.

OEM

PROCESS AUTOMATION

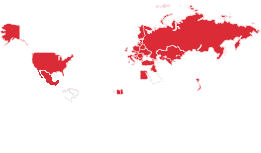

| Process automation is the use of technology to automate business processes to sequentially transition from one task to the next with minimal human intervention. It finds global application across functions and organizations. |

- Process instrumentation and equipment sales and support

- Preparation of PLC and SCADA software and cable lists according to a preferred type of customer turbines

- Basic and detail Engineering

- Plant Production Testing

- Hot and Cold Tests

- Assembly and Installation Supervision

- Documentation

- Training

- Customer technical support, maintenance and service

- Motion Control Systems

- Speed Control Systems

- PLC, SCADA, HMI software and services

- Automation Panels production

- Design and engineering services Factory-Electric Project and Commitment

- Power generation panels

- Compensation panels production

- Plant compensation control

- Motion-controlled special machine manufacturing

OEM

WATER TREATMENT PLANTS

| To the uninitiated, SCADA may seem like just another chunk of consonants and vowels floating around in the alphabet soup of today’s culture. But a SCADA system is, in reality, an extremely important application of computer technology that has created huge gains in productivity and efficiency in the processing industries. |

- Electrical design according to the systems' P&I diagrams

- Manufacture of the MCC-PLC-Remote I/O-RT panels

- Making appropriate PLC-SCADA-RT software-OP Process

- Line pressurization, wells, water tank and pump automation and tracking data with SCADA by PLC and RTU-controlled automation systems, wired and GPRS and wireless wells automation, water production and consumption tracking systems, water treatment automation with SCADA

- Turning pumps on and off according to the pump operating time

- Get in and out the cycle in any desired period and providing redundancy

- Deactivation of the pump according to the bearing and stator temperature and taking (or replacement) the pump with the least use in that instead

- Alarms registration according to the flow and pressure changes profile of the started pump.

- Providing wireless, wired and optical fiber communication between the central water tank and/or pump station and the well or spring water source.

- The total amount of water transferred in this system, temperature trend of bearing may be monitoring and recorded to be analyzed retrospectively.

- A failure notice can be sent to a predetermined e-mail address via the web and also send SMS more than one GSM phone simultaneously.

- Service center can connect to the PLC/RTU system via dial-up and radio modem

OEM

MINNING AUTOMATION

| We are experienced in providing SCADA and Automation solutions for Mining applications. Save time and resources by entrusting your SCADA and Automation problems. Given how rapidly customer demands are growing, it is critical to automate processes in order to stay relevant and profitable |